Applications of Pressure Die Castings:

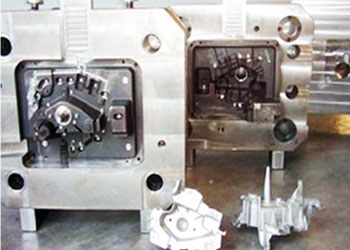

Automotive Industry:

Engine Components: PDC is commonly used for manufacturing engine blocks, cylinder heads, pistons, and transmission components, ensuring strength, precision, and durability.

Suspension Parts: recise and lightweight suspension components like control arms and knuckles benefit from PDC's efficiency and consistency.

Aerospace Sector:

Aircraft Components: Pressure Die Castings are used for producing aerospace components, including complex aircraft structural parts, engine components, and aircraft interior elements.

Space Exploration:PDC plays a critical role in producing lightweight and reliable components for space exploration missions.

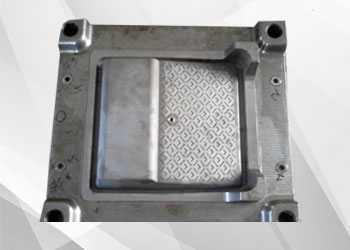

Consumer Electronics:

Laptop Housings: PDC creates sleek and durable laptop housings with intricate designs, meeting both aesthetic and functional requirements.

Smartphone Frames:Precision-made smartphone frames benefit from PDC's ability to produce thin walls with exceptional structural integrity.

Medical Devices:

Imaging Equipment: PDC is employed to manufacture components for medical imaging devices, such as CT scanners and MRI machines, where precision and durability are paramount.

Dental Instruments: Dental equipment, including instrument casings and components, are made using PDC for their reliability and accuracy.

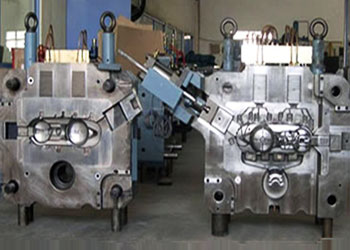

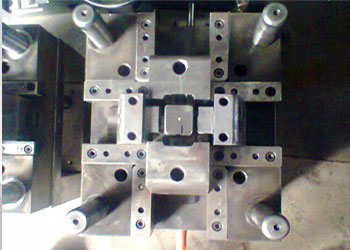

Industrial Equipment:

Pump Housings: PDC is used for manufacturing pump housings, impellers, and valves, which require high-pressure resistance and corrosion resistance.

Power Tools: Precision-made parts in power tools benefit from PDC's ability to create intricate shapes with excellent mechanical properties.