With 15 years of experience, Sai Precision Tools has established itself as a leader in the field of customized plastic mould manufacturing. Our team of skilled engineers and technicians works closely with clients to design and produce moulds that deliver exceptional results. We pride ourselves on our state-of-the-art facilities, cutting-edge technology, and unwavering dedication to quality.

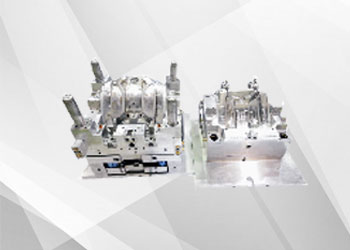

At Sai Precision Tools, we specialize in crafting customized plastic moulds that are designed to meet your specific needs and applications. Our commitment to innovation and precision makes us the trusted partner for industries seeking tailored solutions for their unique projects. In this article, we will explore the world of customized plastic moulds and showcase their wide-ranging applications.

We Perform Professional Plastic Mold R and D and assembling, including finished item drawing survey, 2D and 3D drawing of expulsions from shape, dimension estimations, and form stream investigation, and so on. Our incorporated generation forms, which incorporate shape plans, shape assembling and Plastic Injection Molding.

Our customized plastic moulds find applications in a diverse range of industries, including:

Automotive Industry

Bumper Moulds: Precision-designed moulds for automotive bumper components ensure durability and safety.

Interior Trim Moulds:Moulds for interior trim pieces contribute to the aesthetics and functionality of vehicles.

Consumer Electronics:

Casing Moulds: Tailored moulds create sleek and functional casings for smartphones, laptops, and other electronic devices.

Button Moulds: Precision moulds for tactile buttons enhance the user experience in electronic devices.

Medical Devices:

Device Housing Moulds: Moulds for medical device casings ensure a sterile and durable enclosure for critical equipment.

Instrument Component Moulds: We craft moulds for intricate components in surgical instruments and diagnostic devices.

Packaging Industry:

Bottle Cap Moulds: Customized moulds produce airtight and tamper-evident bottle caps for various products.

Container Moulds: Moulds for packaging containers enhance product protection and presentation.

Industrial Equipment

Fasteners : We design press tools for producing a wide range of fasteners, from screws to nuts, that meet industry standards.

Custom Components: Our press tools create bespoke components for industrial machinery, improving performance and reliability.

Benefits of Our Press Tools

Conclusion

Customized plastic moulds are at the heart of many industries, driving innovation and precision in manufacturing. At Sai Precision Tools, we understand the importance of precision, design flexibility, and efficiency in creating moulds that cater to your unique requirements. Contact us today to discuss your project and discover how our customized plastic moulds can elevate your production processes.

Sai Precision Tools is a strong player in manufacturing and supplying quality based plastic injection moulding products. A company that has consistently achieved outstanding customer satisfaction has done so, due to its innovative ways to manage products, processes and people, coupled

Read More